The production process of enamel mug.

1. Choose high-quality metal substrate

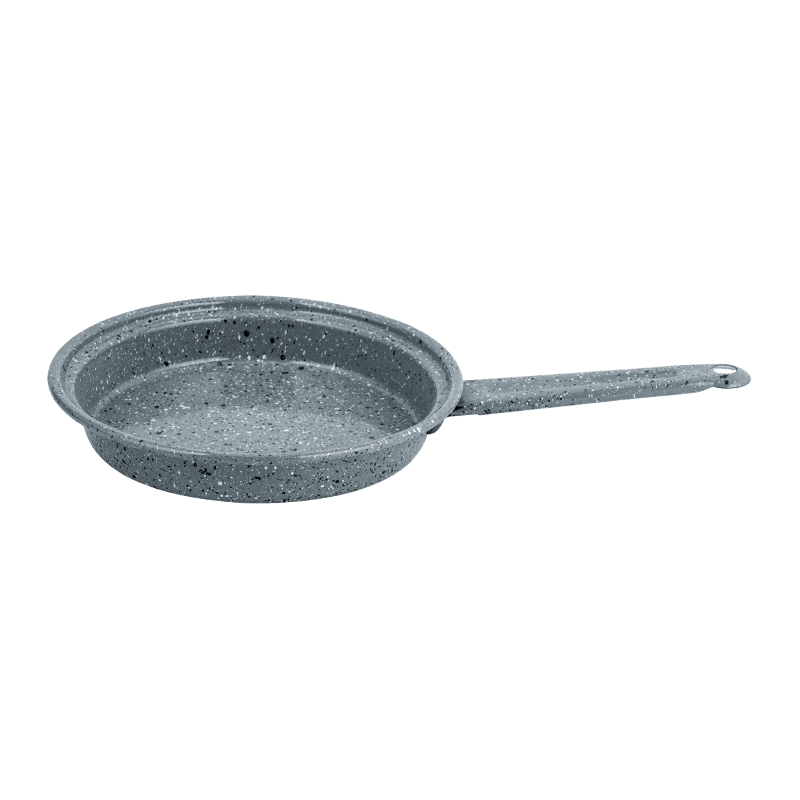

The basic materials of enamel cups are high-quality metals, which have good strength, corrosion resistance and excellent thermal conductivity, ensuring that enamel cups can be stable for a long time during use. Stainless steel is used as the substrate, which has excellent corrosion resistance, high temperature resistance, acid and alkali resistance, and is widely used in hot drink cups in daily life.

2. Metal cup body molding

Cutting and stamping: Cut the metal sheet into a suitable size, and then shape the metal sheet into the basic shape of the enamel cup through stamping or mold processing.

Stretching: Through a special stretching process, the metal cup body is formed into a round or other required shape to ensure that the cup body is uniform and smooth.

Welding and connection: When the enamel cup is designed as a multi-part structure, it is necessary to connect the various parts tightly through welding technology to ensure the firmness of the cup body structure.

3. Enamel coating process

Apply enamel glaze: Apply enamel glaze evenly on the metal cup body. Enamel glaze is made by melting a variety of natural minerals and glass components, and has the characteristics of high temperature resistance, wear resistance, and corrosion resistance.

High temperature firing: The metal cup body coated with enamel glaze is placed in a high temperature furnace for firing, and the temperature is usually 800℃ to 850℃ to ensure that the glaze is closely combined with the metal surface to form a solid protective layer.

Cooling and curing: After high temperature firing, the enamel cup will be cooled naturally to completely solidify the enamel glaze, forming a hard and smooth surface, providing better protection.

4. Fine grinding and finishing

After the enamel glaze layer is fired, there may be slight flaws on the surface of the enamel cup, so it needs to be finely trimmed to ensure that every detail is perfect.

Grinding and trimming: Use professional grinding tools to polish the surface of the enamel cup, remove excess enamel coating and burrs, and ensure that the cup mouth is flat and comfortable.

Polishing: Polish the surface of the cup to enhance its surface gloss and make it more beautiful.

5. Quality inspection and packaging

Appearance inspection: Check the appearance quality of the enamel cup to ensure that there are no bubbles, cracks or other defects.

Functional test: Test the insulation performance, high temperature resistance, corrosion resistance and other functions of the enamel cup to ensure its good performance in actual use.

Packaging: The enamel cups that pass the inspection will be safely packaged to prevent damage during transportation and ensure that the final consumers can receive high-quality products.

6. Quality Assurance

Yuyao Zhili Metal Products Co., Ltd. is committed to the research, development, production and sales of daily steel plate enamel products. The company adheres to the business philosophy of "intelligent manufacturing, based on innovation", always adheres to independent innovation, and is committed to providing the market with high-quality and high-performance enamel products. The company has obtained more than ten patent certificates issued by the State Intellectual Property Office through continuous research and development of new products, new technologies and new processes. The enamel cup does not contain harmful substances and meets the safety standards of food contact materials to ensure the health of consumers.